Today I bottled the beer that I made with the BrewSmith kit, which I wrote about here.

The beer fermented for two weeks and four days, which is a little longer than the kit suggested. It took this long was because it has been a fairly constant 16°C inside, which is just right for a steady ferment. If it had have been the height of summer then it would have fermented out in about a week.

I moved the demijohn from the indoor kitchen to the outdoor one to perform the bottling. This is what the demijohn looked like after the beer finished fermenting. The liquid had cleared right up, and the majority of the yeast had sunk to the bottom.

A good indication that fermentation has completed is when the airlock water levels out and all bubbling stops.

You can see the clarity of the beer in this close up. The airlock activity stopped about two days ago, so I find that if you leave it for two additional days, the clarity improves and there is very little sediment in the final product in the bottle.

Speaking of bottling, here is my table capper that I use with crown seals. All set up and ready to begin capping.

However, before capping I had to wash the one dozen 375ml bottles in sanitizer solution and give them a scrub with the bottle brush. They were all fairly clean because once I finish a beer, I give it a rinse with tap water before putting it away for the next brew.

Today, I also removed all the old labels and gave the outside of each bottle a scrub to remove any residual label glue. All nice and clean and ready to go.

To assist in carbonation, I added one of these specialist brewing sugar drops to each bottle. This process is called priming. It just cuts down work using these drops.

The old school method is to use a funnel to add half a teaspoon of white sugar to the bottom of each clean bottle. The sugar is fermented by the little remaining yeast in the beer and creates CO2 bubbles and a little additional alcohol (about 0.5%).

As you can see, I syphoned the beer out, using the provided hose, into the clean and primed bottles. You fill them to the top because when you remove the hose the beer level is just right, about 2.5 cm (1 inch) from the top.

Here is a filled bottle on the capping tool, with the crown seal on top just before pulling down the handle.

And a side view for those who have not seen this process before. Once the cap is sealed, you need to invert the bottle a few times to dissolve the sugar. It only takes a few inversions for this to happen.

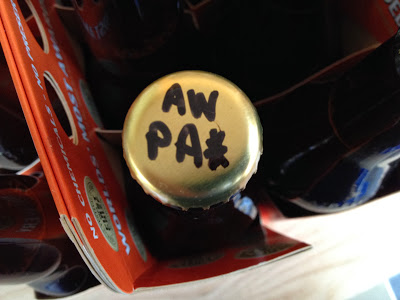

Once all the bottles are sealed, and the priming sugar dissolved, then you need to record the bottling date somewhere (I have in with this post), and mark the batch.

I write on the caps with permanent marker. In this instance I wrote the type of beer, which is Aussie Wattle Pale Ale. Note the little asterisk. I always mark the last bottle as it usually has a lot more sediment in it, so this lets me know that I have to decant into a glass before drinking.

There you go. All bottled and placed in some old six pack holders for storage. I put them in my stockpile cupboard on the floor. It is a nice constant 16-18°C so the secondary fermentation will do its bubbly magic in a short time span.

This home brew will now be ready to drink in about three weeks and I will let you know what they are like and how the beer turned out.

The entire process was great fun, and it only took about an hour from start to finish. Well worth the cost of the kit seeing that two six packs of premium beer would cost about $40 in the liquor store!

If I get time this weekend, I will put down a larger 23 litre brew, this time a Cerveza. Just in time for pool weather!

So dear readers, hopefully you can see how easy it is to make beer with one of these kits, completely from scratch. I am looking forward to the taste test. Fingers crossed, it should be a nice beer.

Who wants to help me sample it? 😉

wow I didn’t realise it was this easy. so in theory, if some one had a kit and started it this weekend it would be ready for Christmas. What an excellent idea

Hi Sol, Yes I am sure that you will have by Christmas you will have great tasting beer! 3 weeks for fermenting, and 3 weeks for secondary fermentation in the bottle.

Gav x

At our factory a couple of the workers and one of the engineers have a brewing operation going on. They discuss it at length after work on Fridays and share the beer. Funny, that they dont seem to drink as much these days as they seem to drink it with appreciation rather than just guzzling. The other day i was roped in to buying for them some hops crowns from Sydney. 5 different types which apparently will be used in different beers once grown. Its very interesting but unfortunately im allergic to alcohol. Now, if you were offering home made ginger beer and a chair beside your gorgeous pool, Jess and I would be in like a shot.

I’ll be there to try a mouthful. 😉 I definitely see a beer kit, probably one of these ones, in our near future though. 🙂

I am happy to donate to you some hop rhizomes for your garden, if you were inclined to grow them. They are lovely bines (not Vines) and die back each year. Great, fast growing and provide you with free, pleasant hops.